Waterstop Grouting Rings

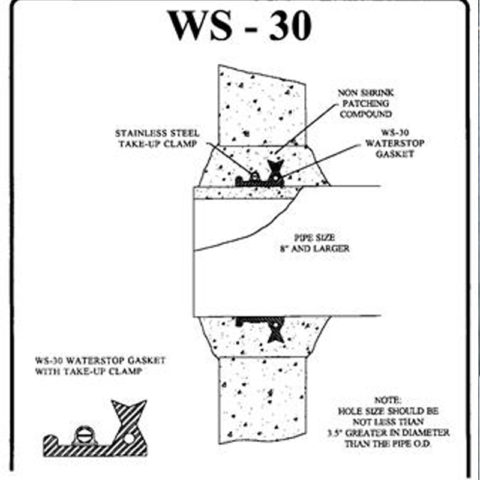

WS Series WATERSTOP (WS-25/ WS-30) is a rubber ring which is compressed around the pipe circumference using Stainless Steel Clamps, pre-venting infiltration and exfiltration between the WS Series WATERSTOP and the pipe. It is then either grouted into an existing structure, or has a new structure poured around the pipe with the WS attached to the pipe.

What It Is

WS Series WATERSTOP (WS-25/ WS-30) is a rubber ring which is compressed around the pipe circumference using Stainless Steel Clamps, pre-venting infiltration and exfiltration between the WS Series WATERSTOP and the pipe. It is then either grouted into an existing structure, or has a new structure poured around the pipe with the WS attached to the pipe.

Literature

Full Literature

How It Works

- Stainless steel clamps secure the connector to the pipe.

- The connector is placed to follow the arc of the manhole wall and the stainless steel clamp is placed straight across the confinement area.

- The pipe is placed in position and grouted in place using non-shrink patching compound OR

- The pipe is placed in position in the formwork and the structure is poured around it.

Why It's Better

- The best alternative to solely using mortar joint compound.

- Adaptable to a variety of field and installation conditions.

- Can be installed with existing, new or poured-in-place structures.

- Nearly unlimited possibilities for pipe size, style or type.

Meets or Exceeds

WS Series WATERSTOPs meet or exceed the material physical property requirements only of the following specifications:

- ASTM C 923 Standard Specification for Resilient Connectors Between Reinforced Concrete Manhole Structures, Pipes, and Laterals

- ASTM C 1478 Standard Specification for Storm Drain Resilient Connectors Between Reinforced Concrete Storm Sewer Structures, Pipes, and Laterals

- ASTM F 2510 Standard Specification for Resilient Connectors Between Reinforced Concrete Manhole Structures and Corrugated High Density Polyethylene Drainage Pipes

Where To Use

- Manholes

- Wet wells

- Square pump and lift stations

- Storm water structures

- On-site treatment structures

- Junction chambers

- Grease interceptors

- Round, arch and elliptical pipes

Please Note

WS-30 Waterstops can be purchased for elipitical and arched pipe in a wide range of sizes.

A Waterstop Grout Ring shall be employed in the connection of storm water pipes and other non watertight applications to precast concrete or poured in-place structures to help control infiltration and exfiltration and to meet the requirements of ASTM D 2321 Standard Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications, Section 7.10-Manhole Connections.

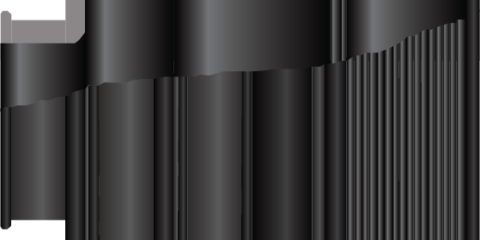

The Waterstop connector shall consist of a rubber gasket and an external take up clamp to secure the Waterstop to the pipe before grouting or pouring in place. The rubber Waterstop shall be constructed solely of synthetic or natural rubber and shall meet and or exceed the physical property requirements of ASTM C 923, ASTM C 1478, and ASTM F 2510.

Minimum thickness of the cross section shall be 0.30 inches (7.6mm) and a minimum of 3-inches (76.2mm) in length. The Keylock portion shall extend into the concrete a minimum of 1.5-inches (38mm) to provide an adequate anchorage for mortar. Non-shrink grout shall be placed around the entire Waterstop and maintain a minimum thickness of 2-inches (50mm) between the rubber gasket and any existing or hardened concrete to permit proper consolidation around the Waterstop connection.

The external take-up clamp shall be constructed of Series 300 non-magnetic stainless steel and shall utilize no welds in its construction.

Selection of the proper size Waterstop and any in field testing requirements shall be in strict conformance with the recommendations of the Waterstop manufacturer. The Waterstop Grout Ring shall be WS-30 Series Waterstop as manufactured by Press-Seal Corporation of Fort Wayne, Indiana or approved equal.